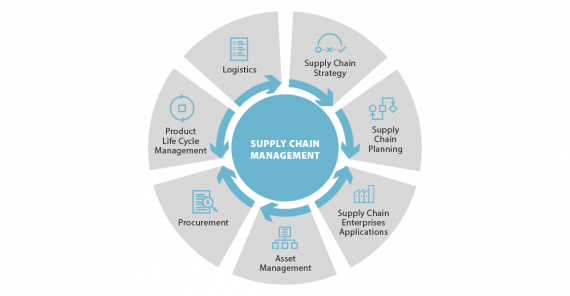

Supply Chain Management

In the aim to satisfy the customer's demands of products and services, we handle the entire production flow. Starting from the raw components all the way to delivering the final product to the consumer. With a strong network of suppliers, adopting new new management solutions ( SCM, CRM,...) our company is able to provide a high quality product by monitoring each step of it conception to the delivery to our partners in charge of the distribution with the end user.

Automated Plant

Dedicated to enhancing production process automation. Create a smart production approach through system integration and establishment of information network in order to offer customers reliable, high efficiency, and high quality products. By respecting world standard certification ISO9001, CE, ROHS, REACH,..., using whole equipment for producing and testing ( Dielectric Voltage Withstand Test, Battery capacity tester, Heating machine, Radium IMEI-SN-ID, Tablet Press Machine, Mobile phone coupling tester, Swaying wire machine, Constant temperature and humidity tester, Drop testing Machine, Transportation Vibration Tester,...) and forming skilled workers.

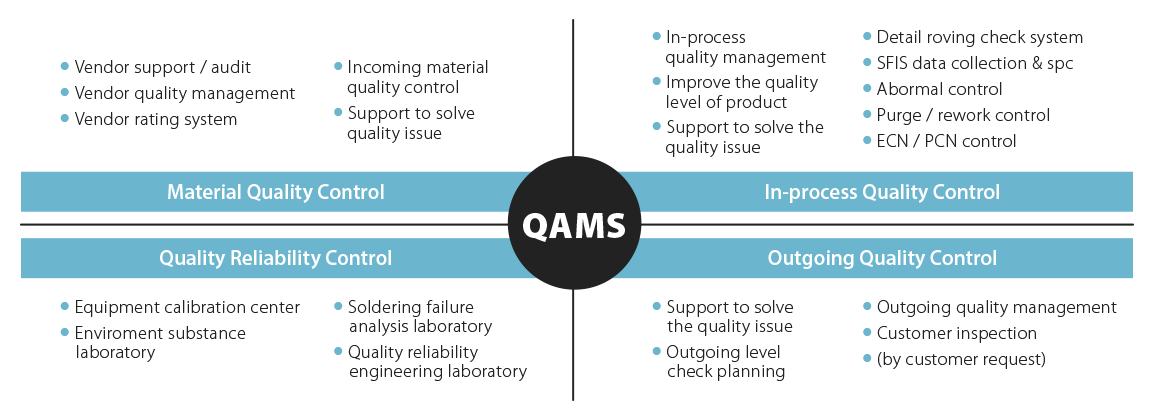

Quality Control Management

A QMS is used to supplier management, incoming quality control, production quality control, reliability testing and final quality control system to serve as production monitoring. Real-time monitoring is implemented throughout the production process in order to control product quality and traceability, thereby ensuring the production of reliable products that comply with the design specifications and the clients’ requirements.